| LA-318 Rebuild

Specifics | Tuning Resources |

Exhaust

Suggestions |

| Engine Swaps | Early Hemis |

Complete Rebuild of LA-318 Engine

1967 Dodge D-100

|

|---|

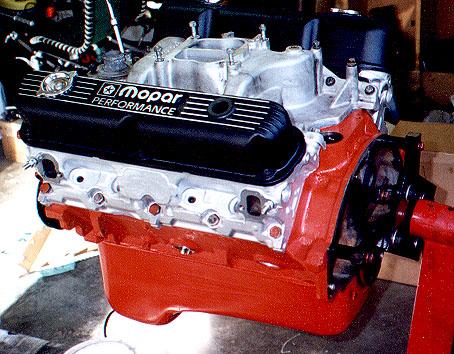

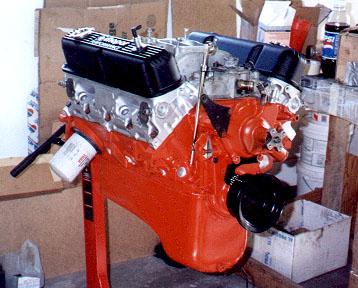

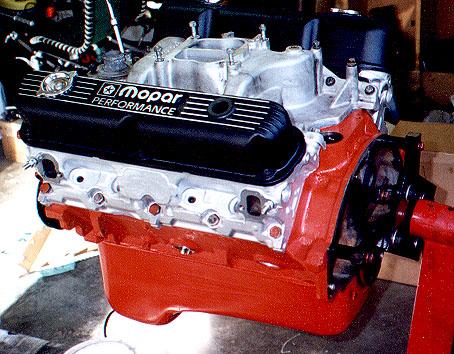

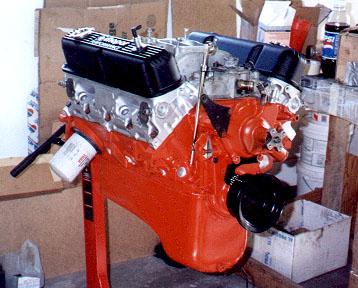

| Engine in assembled form, prior to reinstallation. For this rebuild, all

internal components were replaced except the crank, rods, pistons and

distributor drive shaft. |

|---|

Subject Vehicle: 1967 Dodge D-100 Longbed

Transmission: T-435 4-spd.

Engine: LA-318 ('73 block, 2bbl 2658920 casting heads)

Rearend: 8 3/4 Anti-Slip (3.91 gears, 741 case)

Owner: Kris Wickstead

TIMELINE

4/6/99 - Reduced power and severe miss leads to diagnosis. Low compression found on

cylinders two and four (all others at roughly 110psi). Head gasket is suspected, so

head is removed. Gasket looks normal, head taken to S&B Machine for magnafluxing and

valve check.

4/8/99 - Small crack found on outside surface of head. Decision made to

completely rebuild engine considering possibility of other mechanical problems.

Quality rebuilt 2bbl. heads ordered from Evergreen Engine Exchange.

4/10/99 thru 4/18/99 - Attended Mini Baja West

`99.

4/20/99 - Engine hoist rented, engine stand purchased. Engine removed from truck.

4/21/99 - Teardown begins, all parts removed from engine. Pistons two, four and

yet another show broken top compression rings (good thing I decided to rebuild

it!).

4/22/99 - Block, crank and pistons/rods taken to S&B Machine for checking and necessary

machine work.

4/23/99 - Rebuilt heads received.

4/24/99 - Cleanup of engine parts (other than short block items) begins.

4/26/99 - Machine shop checked over engine, recommend polish crank and hone

cylinders. Work approved and Sealed Power overahaul kit ordered from S&B.

4/26/99 thru 5/3/99 - Cleaning of engine parts continues.

5/4/99 - Engine block, crank and pistons/rods received from S&B Machine. Reassembly

begins.

5/5/99 thru 5/10/99 - Reassembly continues until engine is completed. Tranny and

bellhousing bolted up and engine prepped for reinstallation.

5/11/99 - Engine back in truck. Accessories and components bolted in.

5/12/99 - Engine fired up on first try. Truck is back on road.

5/20/99 - First oil change after 500 miles on rebuilt engine.

5/21/99 - After just over 500mi, engine checked. Compression on all cylinders is 120

psi and all spark plugs clean.

| Mileage Figures: |

|---|

| Total vehicle mileage: | 197,067mi |

| Mileage (reading) at rebuild time: | 97,067mi |

| Recommended break-in: | 1,000mi |

| Mileage (as read) after first oil change: | 97,663mi |

| Mileage after break-in: | 98,067mi |

REBUILD NOTES

|

|---|

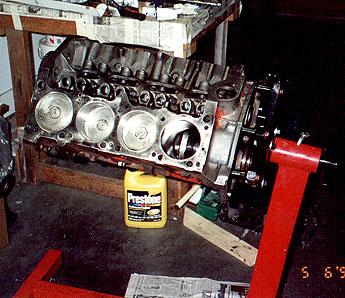

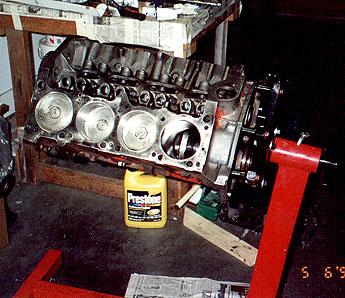

| Block and original forged crank as received after machining. Core plugs

(with "VOID IF REMOVED" overheat pop-up tabs!) had been installed by S&B Machine as

were the cam bearings. All remaining work was performed by the author with the help of

Jim Pedersen and others. |

Purpose for rebuild: Inconclusive diagnosis of engine miss suggests bad rings.

Lack of evidence to show that heads or gasket had failed. Unknown condition of short

block components.

|

|---|

| Engine block after placement on engine stand. Block was very

clean throughout, but was double-checked with a Summit Racing Engine

Brush set. Small particles were found in only a couple of the oil passages.

It never hurts to double-check! |

CRANKSHAFT

The forged crank was pulled from the 318 and measured to be cut 0.010" down from

stock. The third main bearing (thrust bearing) showed some signs of excess wear. S&B

Machine recommended that the crank be polished to remove light scratches and bearing

material. A 0.020" under cut was not required.

|

|---|

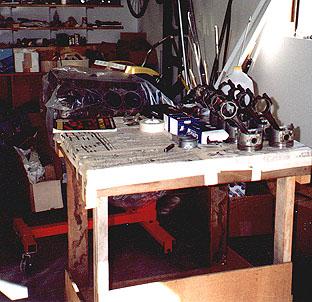

| Pistons and rods organized on clean work surface prior to

installation. Having a table and your parts organized really helps to insure a

thorough job is done during assembly. Note plastic bag protecting engine block from

potentially damaging foreign particles. |

PISTONS/RODS The pistons and rods were removed and inspected. Pistons

from cylinders two and four had broken top compression rings. These rings were broken

directly in half and were still in the upper ring groove when removed. A third piston

had a similiarly broken top ring found to be in multiple pieces (although the entire

ring was still in the upper ring groove). All rods had been marked during a prior

rebuild and were in acceptable condition. These were all cut 0.010" under during a

previous rebuild and were not modified from this state.

|

|---|

| Here, pistons 1, 3 and 5 have been installed. This is probably the most

well-lubricated part of the job, where the rebuilder(s) get as oily as the pistons

are. A band type ring compressor was used to install the pistons in their bores.

|

SHORT BLOCK

After removing the pistons and rods, crank and camshaft, the block was inspected. Only

light scratches were seen in some of the cylinder bores and most of the others still

showed a good crosshatch pattern from the last full rebuild. Measurement of all bores

showed a maximum of 0.003" wear, so a 0.060" overbore was not required on the already

0.040" over cylinders. The block was cleaned and all cylinders were honed. New core

plugs were installed by the machine shop as were cam bearings before the block was

returned. Prior to installing any new parts, all oil passages through the block were

checked with the 6-piece Summit Racing Engine Brush kit. A new Melling oil pump

was bolted on along with a new oil pump pickup tube, also from Melling. To

properly connect the crank and cam, a Melling true roller timing chain was

installed with a standard woodruff key (no timing offset). Moly lube was used to

coat all bearings and wear surfaces prior to assembly. Pistons/rings were dunked in

motor oil shortly before installation and all ring gaps were offset as recommended

by the Sealed Power ring instruction sheet.

|

|---|

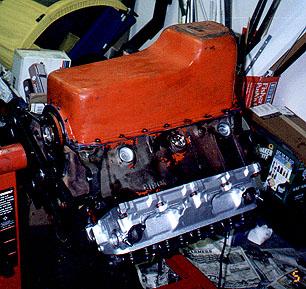

| This front, right side view shows the crank and camshaft

installed along with the true roller timing chain and fuel pump

eccentric. Pistons in the 2-4-6-8 bank are not yet installed. |

CAMSHAFT

As installed from my own rebuild job in high school, the MTD-1 camshaft was removed and

inspected. It had minimal wear on all lobes with only the tips of each lobe fully worn

from edge to edge. For this rebuild, new cam bearings were installed and a new Melling

MTD-1 cam with new lifters were installed. Moly lube was used to coat all components

prior to startup and the lifters were soaked in motor oil prior to installation.

Camshaft Specs: Melling MTD-1 Cam

|

Duration | Timing |

Cam Lift | Lobe Lift |

Lobe Centers |

|---|

|

Int. | Exh. | BTC | ABC | BBC | ATC |

Int. | Exh. | Int. | Exh. | Int. | Exh. |

|---|

| SAE | 278 | 288 | 26 | 72 | 75 |

33 | .281 | .296 | .422 | .444 | 108 |

116 |

| @.050 | 204 | 214 | -6 | 30 | 43 |

-9 | | | | | |

|

|---|

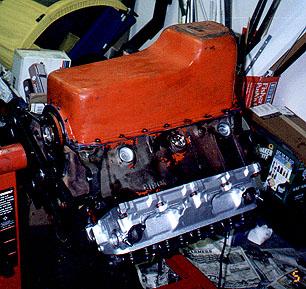

| In this photo the heads, intake, front cover, water pump, and

valve gear has all been bolted on and torqued. New Melling Rocker Shafts

holding Mopar Performance Extra Thick Stamped Rockers perfectly compliment the other

performance enhancements made to this 318. |

HEADS

Initially, the 2-4-6-8 bank head was suspected as the culprit for engine problems as

stated above (see TIMELINE). Luckily the engine was torn down further, as the small

crack discovered in the head was found on the outside surface of the head

between the front exhaust port and the corner head bolt hole. This was obviously not

the cause for major engine problems! Nonetheless, the head was cracked for whatever

reason and thus a rebuilt set of heads were ordered from Evergreen Engine Exchange in

Spokane, WA. Since the old heads were questionable in regards to whether they had

hardened valve seats and the guides had already been knurled once, it was a good deal

to just exchange them for better heads. The replacement set of heads came with new

valves, springs, guides, and hardened valve seats all of which were complemented with a

three angle valve job. For rocker arms and rails, new Melling rails replaced the old

ones and the Mopar Peformance Hydraulic Rocker Arm Kit added 16 new rockers with

thicker cross-sectional material at the pushrod socket (P4529742). The original

pushrods were all in straight, acceptable condition and were retained.

|

|---|

| To put the oil pan on, the engine was flipped over on the

stand. Note pad-type oil pan heater (affixed to sump of pan) to help fight extra cold

Washington winters. |

TRANSMISSION

The NP-435 transmission remained unchanged, although a new clutch pressure plate,

throwout bearing and pilot bushing were installed as a result of this rebuild.

Clutch Specs: 11" disk, 10 spline (1"dia.).

Replaceable throwout bearing was pressed onto existing housing.

|

|---|

| Painting the engine was simply a matter of careful masking and

proper cleaning. Lacquer Thinner was used on clean rags to remove oil and lube residue

prior to painting the engine with a rattle can. The engine block, tranny and

bellhousing required just over one can of paint. The heads required

about a third of a can. |

MISCELLANEOUS

Improvements not in any of the above categories include a core plug type heater, Mopar

Performance Cast Aluminum Black Wrinkle valve covers (P4529026), rebuilt water pump,

new hoses and V-belt, Mopar Performance Chrome Distributor Hold Down Clamp (P4349278),

180° thermostat, and Mopar Performance bronze distributor drive shaft bushing

(P1737725).

|

|---|

| Bolting on the Mopar Performance

Black Wrinkle Finish Cast Aluminum Valve covers really set the engine off. The great

thing is that it runs as good as it looks; something you might worry about when you're

spending all that time and money on a project like

this. |

In the engine, Sealed Power cast iron piston rings were used along with Michigan 77

Engine Bearings and Fel-Pro Gaskets. The engine was painted with Dupli-Color's

500° High Heat paint with Ceramic (block C#%vy Engine Orange, heads Aluminum). The

hedders also got Dupli-Color's 1200° High Heat paint in Black.

All of the speed parts added prior to this rebuild were retained, including the Heddman

Hedders, Edelbrock Intake Manifold and 600CFM Carburetor, Chrome Flexi-fan and

Mopar Performance Electronic Ignition.

|

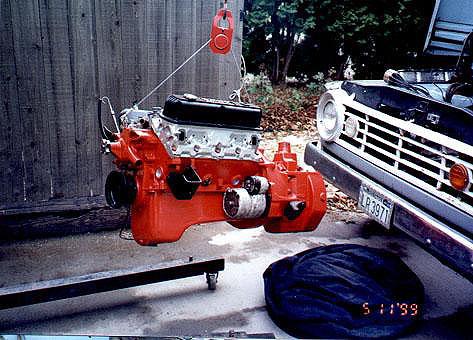

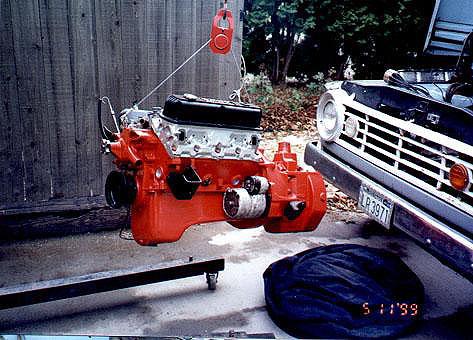

|---|

| This is getting to be more fun now that you've got a 700lb

assembly hanging a few feet off the ground. The assembly comes out and goes back

in quite easily with the L-shaped rear-engine mounts, although it still requires some

creative jockying to get the tranny casing past the firewall. |

RECOMMENDED BREAK IN

After assembly, the engine was filled with a detergent-type Valvoline Super HPO SAE 30

weight oil. The Mopar Performance Oil Pump Primer Rod (P4286800) was used to pressurize

the oiling system prior to startup. On first startup, the camshaft must be broken in by

running the engine at 2,000rpm for twenty minutes. As recommended by the folks at S&B

Machine, the best break in therafter involves 1,000miles of driving under 3,000rpm at

all times while not running at the same rpm for long periods. At 500 miles, the SAE 30

weight oil was drained and replaced by Castrol GTX 10W-30.

Special thanks to: Jim Pedersen, Tom Munck, Jason Heineman, Rick Shimskey, Lance

at Evergreen Engine Exchange, Bryce at S&B Machine.

|

|---|

| The finished product, fully installed. Driving impressions are the finest

reward for any rebuild, and my feeling is that this engine really cooks! Carefully

picking the best performance enhancements and buying quality parts will make any

rebuild a success. |

COST REPORT

| Kris' 318 Engine Rebuild Cost Sheet |

| Item | Date | Description |

Cost | Supplier |

|---|

| 1 |

Unk. | Gaskets, Sealant, Leakdown Tester

Rental | $Unk. |

4th Ave. Shucks |

|---|

| 2 | 4/20/99 |

1,000lb Engine Stand | $64.79 | Clearwater

Shucks |

|---|

| 3 | 4/20/99 | Engine Hoist Rental (2-day) |

$34.56 | Bennett Rentals |

|---|

| 4 |

4/22/99 |

Dupli-Color Engine Paints (1200° Black, 500° C#*vy Engine Orange &

500° Alum.) |

$22.63 | Clearwater NAPA |

|---|

| 5 |

4/22/99 |

Rebuilt 2bbl Heads (new hardened seats, guides, rails and hardware) plus $10

freight |

$334.13 | Evergreen Engine Exch. |

|---|

| 6 |

4/24/99 | Sandpaper, Lacquer Thinner, Scotch-Brite, Rags |

$22.00 | Pay-n-Pak Clearwater |

|---|

| 7 |

4/27/99 |

MP Valve Covers, MP Extra Thick Rocker Arms, Engine Brushes & MP Oil Pump

Primer |

$175.15 | Summit Racing |

|---|

| 8 |

4/27/99 |

Coolant Hoses, Clamps, Chrome Dipstick Tube, Thermostat |

$59.75 | Clearwater NAPA |

|---|

| 9 |

4/28/99 |

Reman. Water Pump & Upper Hose | $30.76

| Clearwater Al's Auto |

|---|

| 10 | 4/28/99 |

Pilot Bushing, Throwout Bearing, White Lithium Lube |

$28.98 |

Clearwater NAPA |

|---|

| 11 | 5/3/99 |

Header Gaskets, Core Plug Heater, Studs & Fine Threaded Nuts, 2nd RTV

Sealant tube |

$39.68 | Clearwater

NAPA |

|---|

| 12 | 5/4/99 |

Engine Machining (clean, remove core plugs, honing, crank polished,

etc.), Overhaul Kit (Rings, Cam & Lifters, Rod-Main-Cam Brgs., Gaskets, Oil Pump

& Pickup Tube) |

$581.87 | S&B Machine |

|---|

| 13 |

5/5/99 | Clutch Pressure Plate | $63.13 |

Clearwater NAPA |

|---|

| 14 | 5/9/99 |

Oberg Engine Tilt-Lift, Anti Freeze, Oil and Oil Filter |

$60.00 | Clearwater Al's Auto |

|---|

| 15 |

5/9/99 | MP breather grommets, MP Engines Manual, MP distributor

hold down clamp |

$39.04 | Summit Racing |

|---|

| | | Total->

| $1,556.47 | |

Write-up Prepared By Kris Wickstead

Updated 6-8-99

Please Note: This page is intended as a guide for the project outlined,

and is not guaranteed in any way. All info above is to the best knowledge of

the author. Comments? Send in an Online Response.

| Engines | Rust |

Common Problems | Interiors | Drivetrain

|

| Main Page | Online Response |

Part Sources |

Sweptline.org Forums |