Frame Swap using `72-`93 Truck IFS

One of the best options for an IFS swap, the `72-`93 Dodge Truck front frame stub is easily overlooked

when customizers attempt to modify their Sweptline Era trucks. On this page you will find information

from two generous enthusiasts; Randy from Minnesota sent along photos of the fabrication process

(scroll down for his article or click here) while Doug Shepherd sent along a

great deal of tips and drawings for this swap. Both swaps utilize a slightly different philosiphy so

be sure to read through both if you're considering this sort of project.

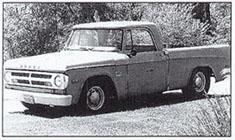

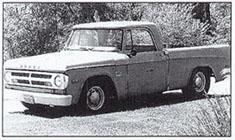

Doug Shepherd's 1970 D-100

While most consider car subframes or front clips, Doug Shepherd of

Raymond, Nebraska wouldn't settle for the lesser components and track width that

these car frames had. He looked to Mopar to find the best possible choice in

swap possibilites and after many measurements were taken of various other

vehicles, he chose the `72-up frame to donate the IFS system he wanted to build

into his 1970 Dodge D-100 Shortbox.

Doug was kind enough to provide some hints for this swap and most of the

information on this page is derived from what he has provided. Read on to find

out more about this awesome swap possibility.

While most consider car subframes or front clips, Doug Shepherd of

Raymond, Nebraska wouldn't settle for the lesser components and track width that

these car frames had. He looked to Mopar to find the best possible choice in

swap possibilites and after many measurements were taken of various other

vehicles, he chose the `72-up frame to donate the IFS system he wanted to build

into his 1970 Dodge D-100 Shortbox.

Doug was kind enough to provide some hints for this swap and most of the

information on this page is derived from what he has provided. Read on to find

out more about this awesome swap possibility.

If you are considering this swap, I'd like to hear from you regarding

measurements, photos and specifics. This page is just a general guide for the

swap, but real photos, accurate measurements and sketches of the fabricated

parts needed would be a real bonus for this page. I (site author) am also

considering this swap, and will post all information plus *tons* of real-life

photos of the job if no one else beats me to it.

GENERAL INFO

In order to graft a more modern suspension system onto your `61-`71 Dodge Truck,

you have a variety of choices for the modern unit you wish to install. Since

the aftermarket is apprehensive about building custom parts for Sweptline Era

trucks, we as enthusiasts have "limited" options in this area when compared with

owners of other American trucks. Nonetheless, a swap of this nature is very

possible and can be done with some planning, the right supplies and extra

time.

The swap is actually quite simple; the Sweptline Era truck frame is cut away at

a certain point and bent inward to accept the matching framerail angle of the

later truck frame stub. This stub would come from a comparable `72-`93 Dodge

Pickup. The swap should be viable for a 1/2 ton or 3/4 ton configuration, but

further information is needed before this can be confirmed. The only major

concern with both trucks is matching the suspension components to the usage of

the truck. Either way, the carefully measured, cut and prepared set of frames

are combined to yield a better handling, more advanced setup for your `61-`71

Dodge Truck.

Benefits of this swap include:

- Disc brakes - Discs were original equipment on `72 and later Dodge Trucks

- Power steering - `61-`71 Dodge trucks were available with this option;

however, the setup on a Sweptline Era truck is somewhat rare, difficult to find

parts for and is considered unreliable by some.

- Aftermarket parts availability - The aftermarket has recognized the later

Dodge Trucks as a more popular configuration and thus provides a number of parts

for the coil spring suspension. This includes anti-sway bars, polyurethane

bushings, dropped spindles and other items. Original equipment parts for these

suspensions are also more plentiful.

- Better handling and control - in comparison to the single I-beam front

suspension of any Pre-`71 Dodge Truck, the `72-`93 suspension system is far

easier to control and has better handling than its predecessor.

Drawbacks of this swap include:

- Overall fabrication effort - If you plan on doing a swap like this on your

own, you need the facilities, time and equipment to do it right. The swap

involves a number of processes which, without experience in fabrication or

welding, may be out of range for the general enthusiast. Nonetheless, a

competent suspension shop would be able perform this kind of swap if you prefer.

- Lower ride height - in comparison to the stock height of a 1/2 ton

Sweptline, Doug Shepherd believes that the truck will ride about two inches

lower. This is not much of a compromise for most, but depending on the kind of

driving you do you may not want to loose any of the ground clearance you already

have. Of course, further frame modifications which are not listed on this page

would yield the stock ride height if you feel strongly about the swap.

SWAP SPECIFICS

To begin, you will certainly want to have a level floor surface to work with.

This way, all of your measurements for the two frames will have an accurate

surface to work from. You can even use the floor as a reference by marking it

with centerlines or other measurements. A level floor will allow you to position

the frames properly so you can secure them for welding. Below is a basic list

of recommended tools for the swap process (this is by all means a partial

list):

| Recommended Frame Swap Tools |

|---|

| Permanent marker | Measuring Tape |

| Ruler | String |

| Welder (MIG) | Cut-off saw (pneumatic) |

| Socket wrench set | Drill w/bits |

| Jack Stands (6-8) | C-clamps and/or

Quick-Grip bar

clamps |

| Engine Hoist | Engine Stand (Optional) |

| Torch | |

Be sure to take measurements of frame height from ground in the natural

riding position of the truck before you start to dismantle. Then, take apart

the front end of the Sweptline Era (`61-`71) truck, remove the motor and tranny,

and take everything down to the bare frame stage. You will most likely want to

remove all of the firewall components such as brake/clutch master cylinders

fluid lines, and the fuel lines so that they are not a hazard when welding is

underway.

Anchor the truck on jack stands at the natural height of the vehicle. If you

choose to set this up so that the truck does not sit at its natural height, no

problem, just measure where the wheels would be off of the ground. Either way

will work, but choose the method that will work best for your situation. The

engine is a consideration here, as when it is out it will cause the front of

the truck to sit higher than normal. Its probably best to take measurements

of frame height from ground in the natural position before you start to

dismantle.

MEASURE TWICE, CUT ONCE

Next, take measurements of all pertinent aspects of both frames. This

includes the track width, frame/truck centerline, axle centerline, location of

crossmembers, engine mount positions, and anything else that will have an effect

on the swap process. Write these figures down and keep them accessible for

reference during the swap. If you are using the floor as a reference for certain

measurements, mark the floor with the engine mount position, axle centerline,

truck centerline, and anything else that may dictate the position of the new

frame stub. Mark the truck centerline onto the firewall as well. You may also

choose to trace out portions of the `61-`71 frame onto the floor so that you can

see exactly how things are shaping up relative to the original frame. Once its

gone, its gone!

FRAME SPECIFICS

`72-`93 FRAME PREP

The `72-`93 frame will be cut where the framerails make the wide turn and become

straight again as they go toward the back of the vehicle. (See image below) You

want to keep the portion of each framerail that angles out, but the bend to

straight is the where you want to make the cut.

`61-`71 FRAME PREP

Once everything has been removed, measured, recorded and marked, one can begin

the removal of the primative frame stub. This involves cutting the Sweptline

truck's frame approximately 8"-12" forward of the firewall. Then, notches are

cut into each framerail at 8"-10" back from the primary cut that was made.

Manual transmission trucks may have some trouble with this swap, due to the

location of the bellhousing crossmember that is located in this region of the

frame. If your truck has a standard transmission, you may have to remove this

crossmember and have a custom unit fabricated. It is tough to say, as Doug

performed the swap on a `68-`71 truck which had a slightly different

crossmember setup than `61-`67 trucks do. If you're planning on swapping

transmissions from a standard to an auto, you may need to get your hands on

an automatic tranny crossmember which will allow you to mount the tranny in

its stock location. See also the tranny section further

down on this page.

`61-`71 FRAME PREP

Once everything has been removed, measured, recorded and marked, one can begin

the removal of the primative frame stub. This involves cutting the Sweptline

truck's frame approximately 8"-12" forward of the firewall. Then, notches are

cut into each framerail at 8"-10" back from the primary cut that was made.

Manual transmission trucks may have some trouble with this swap, due to the

location of the bellhousing crossmember that is located in this region of the

frame. If your truck has a standard transmission, you may have to remove this

crossmember and have a custom unit fabricated. It is tough to say, as Doug

performed the swap on a `68-`71 truck which had a slightly different

crossmember setup than `61-`67 trucks do. If you're planning on swapping

transmissions from a standard to an auto, you may need to get your hands on

an automatic tranny crossmember which will allow you to mount the tranny in

its stock location. See also the tranny section further

down on this page.

These notches (shown in red) will allow you to bend

the early truck frame at an angle inward that will match the angle of the

`72-`93 frame stub you are adding. Consult your measurements or make more

regarding the later truck frame and the angle that is needed. Use a torch to

heat one side of the frame around the area where the bend will be made, then

bend the frame to the angle matching the later frame stub. A jig or mock-up may

be useful during this portion of the process. Muffler shops use welding rod to

get the general shape they want before bending their tubing. You can use the

same process here, but you may want to consider using a larger material such as

angle iron to simulate the proper angle.

These notches (shown in red) will allow you to bend

the early truck frame at an angle inward that will match the angle of the

`72-`93 frame stub you are adding. Consult your measurements or make more

regarding the later truck frame and the angle that is needed. Use a torch to

heat one side of the frame around the area where the bend will be made, then

bend the frame to the angle matching the later frame stub. A jig or mock-up may

be useful during this portion of the process. Muffler shops use welding rod to

get the general shape they want before bending their tubing. You can use the

same process here, but you may want to consider using a larger material such as

angle iron to simulate the proper angle.

As you can see in the above image, the frame stubs have been bent inward so they

can accept the matching angle of the more modern frame. Weld up the notches

once you are certain that the angle is correct. It is suggested that you also

use plates on top of the welded notches to further strengthen the modified area.

Doug recommends plates that are 1.5" wide and 8" long.

As you can see in the above image, the frame stubs have been bent inward so they

can accept the matching angle of the more modern frame. Weld up the notches

once you are certain that the angle is correct. It is suggested that you also

use plates on top of the welded notches to further strengthen the modified area.

Doug recommends plates that are 1.5" wide and 8" long.

MERGING THE TWO FRAMES

At this point, you should be ready to mate the modern truck frame to the

modified Sweptline truck frame. Move the `72-`93 truck frame stub over the bent

portions of the older truck's modified frame. Measurement is crucial here,

where the wheelbase and tracking of the vehicle is in your hands. You will

certainly want to measure the front wheels relative to the rear wheels and check

the centerlines for the wheels (both longitudinal and transversal). Once you

have checked these measurements don't forget to check the side to side widths,

the diagonal squareness of the two frames, and the height from ground.

The image above shows both frames, with the overlap highlighted in magenta. As you can see, the matching

angle of both frames after being modified provides an excellent mating surface

for welding and strength. Once you are sure that all measurements match up and

everything has been double checked, tack weld the two frames at a couple of

points. Then, recheck all of your measurements. Once the measurements have all

been verified, you will want to drill the two frames (somewhere along where they

mate) to accept 1/2" grade 8 flange-headed bolts. Two per side are enough to

hold everything together for welding. Again, re-check your measurements as you

perform these operations, you'll be glad you did.

The image above shows both frames, with the overlap highlighted in magenta. As you can see, the matching

angle of both frames after being modified provides an excellent mating surface

for welding and strength. Once you are sure that all measurements match up and

everything has been double checked, tack weld the two frames at a couple of

points. Then, recheck all of your measurements. Once the measurements have all

been verified, you will want to drill the two frames (somewhere along where they

mate) to accept 1/2" grade 8 flange-headed bolts. Two per side are enough to

hold everything together for welding. Again, re-check your measurements as you

perform these operations, you'll be glad you did.

Once you have the bolts tight and the measurements are correct, you can proceed

with finish welding to achieve a solid frame.

WHAT ABOUT THE REST?

Mating the two frames was the bulky part of the job. Now you have to deal with

mounting the front sheetmetal and bumper, adapting the steering column to box

rod and U-joints, preparing the brakes and fluid lines, as well as the engine

and tranny stuff.

ENGINE AND TRANSMISSION MOUNTING

If you have a automatic transmission truck, you should have no problem by using

the same brackets and crossmembers to mount the Sweptline engine back into its

new home. The alignment should match up well, but your measurements of both

trucks will have to verify this. If you are planning to go with a change of

transmission or have a standard tranny, your job gets a little tougher.

STANDARD TRANSMISSION TRUCKS

These trucks have a crossmember that the bellhousing rests on and bolts to which

is towards the front of the truck near the firewall. The standard tranny

(usually the NP-435 or NP-420) then bolts to the beefy bellhousing which

provides enough strength for the whole assembly. This crossmember can most

likely stay in the frame even though it is very near the area that the more

modern frame stub attaches to.

TRANNY AND ENGINE SWAPS ALONG WITH THE FRAME SWAP

There are a great deal of possibilities that would pertain to this portion of

the job; however, there is simply no way to address all possible combinations

of engine and tranny that could be had in these trucks. Basically, if you're

keeping the tranny, then don't worry about the crossmembers. If you're changing

tranny, you'll need the crossmember that corresponds to the tranny you want to

install unless it isn't a Chrysler tranny. For engines - slant six, small

block and big block engine mounts can be purchased for the `72-`93 frame along

with the rubber isolators. When in doubt, try to mimic the factory

configuration as best as possible.

STEERING

The tough part of adapting this frame, besides welding it into place properly,

is probably the change of steering and how to adapt your column to the relocated

box. This involves adding an adapter, steering U-joints and a long steering rod

to go from the old column to the box located towards the front of the engine.

If your `72-`93 truck frame stub came with power steering, you will also need to

add a power steering pump which merely involves locating the proper brackets and

hoses for the more modern truck application. You can get the brackets from a

junkyard or order them from a reseller.

This steering rod will have trouble clearing the upper A-arm of the more modern

suspension. To get the proper clearance simply grind away a small portion of

the A-arm that is the obstruction, just enough to get the extra room you need.

Removing too much will jeopardize the strength of the A-arm.

Some may choose to change the column while performing this swap. The column

from the `72-`93 truck can be added to the Sweptline, or you can purchase a

custom column from one of the many aftermarket companies that offer them.

Contact Borgeson Universal Company for all your needs in steering U-joints,

intermediate steering shafts, slip joints, and other related items.

Information:

Borgeson Universal Company, Inc.

187 Commercial Blvd.

Torrington, CT 06790-3098

(860)-482-8293

Fax: (860)-496-9320

Check with Ididit Incorporated for custom steering columns. They offer tilt

columns with all the accessories to compliment your truck's interior. Columns

from Ididit are available in various lengths to properly fit a wide range of

applications. Information:

Ididit Inc.

11353 Tecumseh-Clinton Rd.

Clinton, MI 49236

(517)-456-4133

EXHAUST

Your exhaust system will definitely need to be revamped if not totally redone

after this swap is performed. Your manifolds will work, but if you have

Sweptline truck headers you'll need a set of `72-up headers from Mopar

Performance, Hedman Hedders or some other

company. Part numbers for these headers are as follows:

- Mopar Performance 318-360 `72-`91 trucks #P4529439 (1 5/8" tubes, 3"

collector)

- Hedman Hedders 318-360 `72-`93 trucks #79080 (1 5/8" tubes, 3" collector)

- Unfortunately, Mopar and Hedman do not currently make Big-Block headers

for `72-up trucks.

BODY AND BUMPER PROVISIONS

You will certainly want to bolt the core support solid to the frame once this

modern frame stub has been added to your Sweptline Era Truck. These front

panels will eventually become damaged along with the cab and possibly other

parts if not secured. I've seen trucks that haven't had their core supports

fixed solid to the frame; the result is severe cab damage (the front mounts

collapse causing the cab to sink). Simply fabricate brackets that allow the

core support bolts to fasten into the frame. You may even be able to drill into

the frame for these bolts, but you will probably need a spacer of some sort to

keep the front sheetmetal supported.

The front bumper from your Sweptline truck can be redrilled to match the newer

mounts, or you can fabricate a set of brackets to adapt the older bumper to the

frame.

Randy's `70 D-200 Subframe Swap

Special thanks to Randy of Minnesota for providing the information and photos in the following

article.

BEFORE THE SWAP

|

|---|

|

|---|

| Photos of Randy's truck, a `70 Dodge D-200 Longbed. This

truck has a 383 and will be accepting the `82 IFS subframe shown in the

following photos. |

|

|---|

|

|---|

| Click on either of the images above to see the

larger version.Shown here is the frame stub from the `82 1/2 ton truck. Note that

the subject truck is a 3/4 ton while the donor subframe is a half

ton. Realistically, the differences will be in the number of

wheel lugs, the size of the brakes, coil spring capacity, and the fact that

the 1/2 ton a-arms and suspension components probably aren't as beefy as the

3/4 ton units would be. |

|

|---|

| Click on the image above to see a

larger version.Randy included this photo of the

control valve and hoses for the OEM power steering setup on his previously I-beam equipped `70

D-200. He states that, "this power steering setup is rickety and I don't recomend it." Randy noted

that the system is difficult to find parts for and the hoses must be

custom fabricated, which is a pain. Randy finally disconnected the

pump after blowing a third hose, having already custom built two of

the existing hoses. |

|

|---|

| Click on the image above to see a

larger version.Here, Randy used two jack stands under the frame at the cab and two

more (not visible in photo) at the rear of the truck to support it during the swap.

|

Randy suggests that the "trick" is to not let the truck move once it's on the jack stands (prior to

cutting off the old frame, of course). He also suggests using a square from floor to frame and make

tons of marks on the floor relating to important measurements or component locations. Along with

that, write down measurements of anything that is important to the swap. Randy took extra care to

ensure that the core support bolt hole measurements of the original frame were accurately recorded

once the truck was on jack stands. He did this to insure that the frame would be properly located to

hang all of the sheetmetal once the job was finished.

One thing to consider in a swap such as this is the squareness of the front wheels relative to the

rear wheels. Randy added that he, "also made marks on the floor towards rear of truck on each side

the same distance from the front of the truck so he could use the marks to check the squareness of the

subframe." This type of precision is CRUCIAL if you ever want the subframed truck to drive straight

down the road once you're finished. You may even want to reference the center of the rear axles to

the front spindles in taking measurements for this swap to ensure success.

|

|---|

| Click on the image above to see a

larger version. This image shows the truck

(supported with the jack stands) with the old I-beam front

suspension cut off. |

Be sure to cut the original truck's frame and the subframe off at a point where will you will have

more than enough material to make the connection between the two frames (i.e. leave a little excess,

then trim later). Randy measured from the front cab mount bracket bolts and cut the `70 truck frame

off about six inches in front of the bolts.

Here's an interesting note; Randy says that the `82 1/2 ton truck frame was only about 1/4" narrower

than the `70 truck frame underneath the cab. He mentioned that if he had this swap to do over again,

that is where he would connect the modern front subframe to the older truck frame. He suggests

removing the cab if this is where you choose to mate the two frames since it would be a major

obstruction and the cab mounts would have to be temporarily removed if the cab was not.

|

|---|

| Click on the image above to see a

larger version.This image shows the two frames

welded together. The actual point where the two meet is behind the

steering shaft stub in this photo. More visible here is the point

where the subframe was notched to allow for it to be spread out to

mate with the `70 truck frame. |

Randy states, "Here you can see the frames together. What I did was trim the flange on the

top and bottom of the subframe and left about 3 inches of it sticking out to

bolt to the truck (`70 truck frame). I had to spread the subframe to get the proper width (so that the

width at the connection point would be the same). I needed to spread each side of the subframe out

one inch. What I did was weld a pipe to the subframe by the

engine crossmember so I could tell how much I was bending each side, which I

completed using a porta power to do the bending. After I notched the subframe about four inches behind

the upper control arm brackets where they are riveted to the subframe, the pipe

was tack welded to the frame in front of where i notched it... that way I could

tell when I bent it out one inch. I did this for each side of the frame." see the drawing included

below for a better description...

Drawing provided by Randy for this article.

Drawing provided by Randy for this article.

|

|---|

| Click on the image above to see a

larger version.This image shows the outside of the

original frame and subframe combo. Driver's side of truck is shown

here. |

|

|---|

| Click on the image above to see a

larger version. Here's a profile view of the

1982 D-100 subframe as attached to the 1970 D-200 Truck Frame from the driver's

side. |

|

|---|

| Click on the image above to see a

larger version.

In this photo, you can better see the

region where the two frame sections were trimmed and then welded.

Randy plans to box the frame from the rear of the front cab mount to

about six inches in front of where the subframe was notched. |

|

|---|

| Click on the image above to see a

larger version.

From Randy's e-mail with these photos:

"Here you can see the power brake master cylinder and booster unit

installed. They are directly out of the donor `82. When I took off the

two bolt non-power master cylinder, I thought I was going to have to

drill holes in the firewall to mount the power brake unit. Conversely,

the holes were already there, I just had to punch them out. There's about

four different sets of holes in the firewall. The holes work like conduit

type outlet boxes--they are stamped into the sheetmetal but not punched

out. You just have to knock out the partially punched holes. I put

the power brake master unit in because the disc brakes require a

different proportioning valve to work right. Also, the master has a

larger bore to work the bigger pistons in the discs (that seems to make

sense)."

|

|

|

|---|

| Click on the image above

to see a larger version. | |

Randy states, " I cut the steering tube off at the bottom (firewall

exit location) of the original `70 truck column to make the first u- joint

higher in the truck about 2 1/2 to 3 inches. (That's what the pic of me

holding the peice of tube is; that's what I cut off.) The steering

works smooth as silk and the joints are greaseable to boot--they should

be around long after the truck is gone."

Randy also mentioned, "I went to the good `ole fleet farm and aquired

some pto shaft universal joints. Got all of it and the shaft (which is

just 3/4 inch diameter solid round stock) for about $45. The joints

are really big for what I'm using them for, but I don't want my steering

to come apart when I'm cruising. I had the tilt column from the donor

truck, but we all know that Mopars have a terrible wiring system to

begin with. As a result, I didn't want to be butchering the `70 harness

to wire in the `82 tilt column. Also, I would have ended up with

two ignition switches (one on the dash and one on the column). That

would have been undesirable even if I had plugged the hole in dash.

|

|

|

|---|

| Click on the image above

to see a

larger version.

|

| I used three joints for the steering shaft to

clear the upper control arm

because it looked really close to it and would have required alot of

grinding to make enuff room. I had to use pillow block bearings to

support the long shaft or it would have flopped around."

|

|

|

|---|

| Click on the image above

to see a

larger version.

|

| These photos show a close up view of the steering

shaft completed. Randy noted, "Here's the front of the coulmn. The tack

welds are pretty obvious here. It looks complicated, but with three

u-joints, I don't have any control arm clearance problems."

|

|

|

|---|

| Click on the image above

to see a larger version. |

|

Randy mentioned, "This is a photo of the front core support mounts where

you see the bolt. The bolt in the photo is located where the `82 core

support bolted on. I had to make a bracket because the older truck core

support sat back about 4 inches, so I just bolted the strap in, then

welded it on." |

|

|

|

|---|

|

Click on the image above to see a larger version.

|

From Randy, "Here's the truck rolled out of garage. It sits about 2 1/2

inches lower now. I welded the frame with the good `ole Lincoln

Stick Welder, since my wire feed isn't hot enuff for that thick

truck frame steel. I used 6013 1/8 inch rods and it welded up

really strong.

Doesn't appear to have any flex at all, so I'm not

sure I'm going to box in the welded section of the frame. I might just

use 2' by 1/4' flat bar stock to weld over the top and bottom flange

right now. With a little grinding, you wouldn't even be able to tell it

was welded (it fit that close, and boxing it would be a problem with

proportioning valve body for brakes--it is bolted inside the

driver's side framerail and would have to be moved for future service

if needed). With the flat stock, I will just tack it to frame at one end

or the other on top of the rail and heat and bend it to match the contour

of that section, then stitch weld it every couple of inches. That should

prove to be strong enough to add the strength back to rails. You cant

make it too solid, because it does need to flex a little or it will crack

and break (not good at all).

|

|

|---|

| Click on the image above to see a

larger version.

Quoting Randy again, "Here's the finished truck minus hood. It sits 3

1/2 inches lower. Frame feels rock solid. I (Randy) drove it and it

handles like a dream. The power steering is great; it turns like it was

meant to. I (Randy) can now let go of the wheel and it goes straight

(even with a worn center link in the front end). It no longer changes

lanes when I hit a bump although it leans a little more on corners than

it did before (needs swaybar)."

Randy had to change front rotors to get the 5 on 4.5 inch

bolt pattern for the wheels that the older half tons had.

Dodge changed the bolt pattern in `81 or `82 to 5 on 5.5 inch, but the

hubs and rotors are apparently interchangeable with the older ones (even

the bearings are the same according to Randy).

|

Last

updated Thursday, January 16th,

2003.

Please Note: This page is intended as a guide for the project outlined,

and is not guaranteed in any way. The information was supplied at the request

of the author and is merely an extension of what was received. All the info is

to the best knowledge of the author. Comments? Send in an Online Response.

| Engines | Rust |

Common Problems | Interiors | Drivetrain

|

| Main Page | Online Response | Part Sources |

Sweptline.org Forums

|