Dates:

12-5-95 - Truck is brought into NCHS Auto Shop. Removal process begins.

12-7-95 - Engine is out; prepped for rebuild.

2-11-96 - Engine is ready to be reinstalled, installation process continues

for next three days.

2-14-96 - Truck is back together and running.

| Mileage Figures: | |

|---|---|

| Total mileage: | 168,648mi |

| Mileage at rebuild: | 68,648mi |

| Recommended break-in: | 1,000mi |

| Mileage after break-in: | 69,648mi |

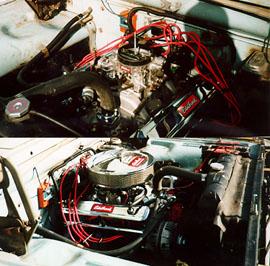

Condition of engine before rebuild: It was determined by an unidentified rebuild plate that previous machining operations had been completed on the engine. On the engine was a 2bbl Bendix Stromberg carburetor with manual choke and a single point distributor. Inside, the crank had been cut .010 over and the cylinder bores were .040 over (as told by the rebuild plate). The 318 was abnormally oily and dirty, showing signs of a leaky rear main seal and bad head gaskets. Upon disassembly, the engine seemed to be well maintained and exhibited very little oil buildup throughout. The freeze plugs were siliconed into their holes, making their removal a nightmare. The intake manifold heat crossover was completely blocked with carbon buildup, and the head passages were partially clogged. All internal components were removed with ease. The only hindrance on disassembly was the crank pulley; this was solved quickly after finding the proper tool for removal (please see below). Both the camshaft and timing chain had little wear, but the chain was stretched enough to warrant its replacement.

Condition of Transmission: An extreme amount of dirt and grime existed on the transmission itself. Some leakage was prevalent out of the covers and the end assembly areas. The clutch disk had been worn down to the rivets, while the flywheel had classic signs of heat checks and wear. These heat checks were also found on the pressure plate, which had weak springs.

Camshaft Specs: Melling MTD-1 Cam

| Duration | Timing | Cam Lift | Lobe Lift | Lobe Centers | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Int. | Exh. | BTC | ABC | BBC | ATC | Int. | Exh. | Int. | Exh. | Int. | Exh. | |

| SAE | 278 | 288 | 26 | 72 | 75 | 33 | .281 | .296 | .422 | .444 | 108 | 116 |

| @.050 | 204 | 214 | -6 | 30 | 43 | -9 | ||||||

Clutch Specs: 11" disk, 10 spline (1"dia.).

Replaceable throwout bearing was pressed onto existing housing.

Notes on Engine Removal: The T-435's dimensions required the complete removal of the four engine and transmission mounting pads and the interior driveline tunnel in order to safely clear the firewall. Once these items were out of the way, the engine and transmission were removed with patience and careful maneuvering.

Notes on Engine Balance: On this particular LA-318 engine, the assembly

including the crankshaft, rods and pistons are "internally balanced". This

means that no outer harmonic damper is necessary to reduce vibration and

balance the motor. Since this vehicle was manufactured in 1967, the first

year for the LA-318 powerplant, Chrysler continued using internally balanced

forged cranks in trucks to make the changeover more cost effective. The

forged cranks and the internally balanced engine are considered "rare", and in

later years Chrysler switched to the current practice of an externally

balanced crank on trucks. In place of the balancer is an extended length

pulley. Take care when removing this pulley, as it requires the use of a

ducks foot (or four-slot) puller. Caution!! Do

not use a 3-jaw pulller, hammer, screwdriver or any other device to attempt to

remove the crank pulley. This pulley can only be removed by threading two

long bolts into its recessed dish and using a ducks foot shaped puller to

slowly remove it from the engine. Two threaded holes are present in the dish

of the pulley--use these for the bolts. The trouble encountered in attempting

to find a replacement for a damaged pulley was next to impossible. Although

the current pulley installed is a two-groove version, the original single

groove unit was bent during improper removal efforts. Nontheless, the two

groove part is a stronger item, and it allows for the addition of accessories

in the future if desired. A stainless steel repair sleeve was placed on the

seal surface to aid in front main seal longevity.

Notes on Engine Balance: On this particular LA-318 engine, the assembly

including the crankshaft, rods and pistons are "internally balanced". This

means that no outer harmonic damper is necessary to reduce vibration and

balance the motor. Since this vehicle was manufactured in 1967, the first

year for the LA-318 powerplant, Chrysler continued using internally balanced

forged cranks in trucks to make the changeover more cost effective. The

forged cranks and the internally balanced engine are considered "rare", and in

later years Chrysler switched to the current practice of an externally

balanced crank on trucks. In place of the balancer is an extended length

pulley. Take care when removing this pulley, as it requires the use of a

ducks foot (or four-slot) puller. Caution!! Do

not use a 3-jaw pulller, hammer, screwdriver or any other device to attempt to

remove the crank pulley. This pulley can only be removed by threading two

long bolts into its recessed dish and using a ducks foot shaped puller to

slowly remove it from the engine. Two threaded holes are present in the dish

of the pulley--use these for the bolts. The trouble encountered in attempting

to find a replacement for a damaged pulley was next to impossible. Although

the current pulley installed is a two-groove version, the original single

groove unit was bent during improper removal efforts. Nontheless, the two

groove part is a stronger item, and it allows for the addition of accessories

in the future if desired. A stainless steel repair sleeve was placed on the

seal surface to aid in front main seal longevity.

Added External Improvements (at time of rebuild): Edelbrock 600 CFM electric choke 4bbl carburetor, Edelbrock Performer 318-360 aluminum intake manifold, radiator refurbished, 18" Flex-Lite flexi fan, chrome dipstick tube, chrome water neck.

Replaced Parts: Melling MTD-1 camshaft, lifters, timing chain and oil pump, Fel-Pro Gaskets, remanufactured clutch disk and pressure plate, Motormite pilot bushing, Federal Mogul throwout bearing, Brass freeze plugs, Dura-Bond cam bearings, Federated thermostat, Fluoroelastomer valve seals, NGK V-Power spark plugs, new temp sender, steel and brass pipe plugs, brass distributor shaft bushing, Krylon Ch%*y Engine Orange paint.

Special thanks to: Dad, Mr. Feldhusen, Mr. Thomas, Mr. Sanborn, Steve, John, Spencer, Casey, Traci, Jones Automotive Engine, General Store Auto, Al's Auto Supply, Summit Racing Equipment, Ingham and Phipps Radiator, Watts Wheel and Driveline.

Write-up Prepared By Kris Wickstead

Updated Version 5-21-97

Please Note: This page is intended as a guide for the project outlined, and is not guaranteed in any way. All info above is to the best knowledge of the author. Comments? Send in an Online Response.