How Dodge Trucks Were Built

This page represents a particular advertisement regarding Dodge Sweptline

Era Trucks which details some specifics about how these trucks were

manufactured. The actual ad was submitted by John Bitter and has been

formatted in HTML so it is more readable.

To see a larger version of the images on this page,

simply click them. A larger image will appear.

All images from

a Dodge Truck

Advertisement.

All images from

a Dodge Truck

Advertisement.  A NEW DODGE TRUCK BEGINS HERE.

With a "Dodge Truck Building Order." Teletyped from a central factory

control point to stations in the plant, the Building Order lists the

components and equipment that go into an individual truck; Engine,

transmission, axles, ratios, tires, special equipment, and others. A copy

of the order is affixed to the cab (shown here) or body, engine, and frame

during the first steps in the assembly process, and accompanies it until

the truck is completly assembled.

A NEW DODGE TRUCK BEGINS HERE.

With a "Dodge Truck Building Order." Teletyped from a central factory

control point to stations in the plant, the Building Order lists the

components and equipment that go into an individual truck; Engine,

transmission, axles, ratios, tires, special equipment, and others. A copy

of the order is affixed to the cab (shown here) or body, engine, and frame

during the first steps in the assembly process, and accompanies it until

the truck is completly assembled.

CAB CONSTRUCTION. Dodge cabs can't

be beaten for strenght and durability over the long haul. Here is why.

To make the structure permanently rigid, roof rails, door posts,

windshield posts, step wells, and cab back (at floor level and belt line)

are of box section construction. To keep the doors from shaking and

sagging, they are solidly hinged to the door posts. Then the completed

cab is attached to the truck frame with thick rubber mounts that

permanently "tune out" vibration and noise.

CAB CONSTRUCTION. Dodge cabs can't

be beaten for strenght and durability over the long haul. Here is why.

To make the structure permanently rigid, roof rails, door posts,

windshield posts, step wells, and cab back (at floor level and belt line)

are of box section construction. To keep the doors from shaking and

sagging, they are solidly hinged to the door posts. Then the completed

cab is attached to the truck frame with thick rubber mounts that

permanently "tune out" vibration and noise.

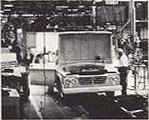

RUST-PROOFING. When you buy a Dodge

truck you can be sure of years of freedom from rust and corrosion. Here

you see why as (on the left) a Dodge cab enters the first of a multi step

process that will give lasting protection to every area subject to road

splash or water accumulation. Rocker panel sills are are double coated;

door interiors are primed on the bottom 12 inches; all box sections have

drain holes. On the right the same cab emerges from the booth.

RUST-PROOFING. When you buy a Dodge

truck you can be sure of years of freedom from rust and corrosion. Here

you see why as (on the left) a Dodge cab enters the first of a multi step

process that will give lasting protection to every area subject to road

splash or water accumulation. Rocker panel sills are are double coated;

door interiors are primed on the bottom 12 inches; all box sections have

drain holes. On the right the same cab emerges from the booth.

PICKUP CAB AND BODY are kept together during the painting process. They

went through rust-proofing together. Now they go through the paint line

together so their finishes will be perfectly matched. Here, near the end

of the assembly line, they are being lowered onto the chassis. The cab

will be attached to the frame with thick rubber mounts that "tune out"

vibration, provide an amazingly quiet ride. Just a few hundred feet more

down the assembly line and this Dodge truck will be complete and ready for

inspection.

PICKUP CAB AND BODY are kept together during the painting process. They

went through rust-proofing together. Now they go through the paint line

together so their finishes will be perfectly matched. Here, near the end

of the assembly line, they are being lowered onto the chassis. The cab

will be attached to the frame with thick rubber mounts that "tune out"

vibration, provide an amazingly quiet ride. Just a few hundred feet more

down the assembly line and this Dodge truck will be complete and ready for

inspection.

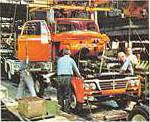

...DOWN THE ASSEMBLY LINE in a lengthwise,

nose-first position. During its journey along the line toward completion,

the slowly growing Dodge truck is inspected continually for quality.

Nothing is left to chance anywhere in the manufacture of a Dodge truck,

from the raw materials it begins with, to the finished product. Dodge

builds tough trucks. It is the sole duty of a large number of

hard-to-please inspectors to make sure that every Dodge truck we built is

a tough truck all the way through.

...DOWN THE ASSEMBLY LINE in a lengthwise,

nose-first position. During its journey along the line toward completion,

the slowly growing Dodge truck is inspected continually for quality.

Nothing is left to chance anywhere in the manufacture of a Dodge truck,

from the raw materials it begins with, to the finished product. Dodge

builds tough trucks. It is the sole duty of a large number of

hard-to-please inspectors to make sure that every Dodge truck we built is

a tough truck all the way through.

A FEATURE OF ALL DODGE

GASOLINE-powered trucks is a 35-amp alternator standard equipment on all

gasoline powered Dodge Trucks built since 1961. The alternator offers you

two big advantages. It keeps the battery more fully charged at all times.

You get faster, surer starts in all kinds of weather. And, because the

battery is more fully charged always it will last far longer than usual. A

larger capacity 40-amp alternator is optional equipment on all Dodge

gasoline powered truck models.

A FEATURE OF ALL DODGE

GASOLINE-powered trucks is a 35-amp alternator standard equipment on all

gasoline powered Dodge Trucks built since 1961. The alternator offers you

two big advantages. It keeps the battery more fully charged at all times.

You get faster, surer starts in all kinds of weather. And, because the

battery is more fully charged always it will last far longer than usual. A

larger capacity 40-amp alternator is optional equipment on all Dodge

gasoline powered truck models.

STANDARD ENGINE AND TRANSMISSION

in Dodge low-tonnage models are a 140 hp Slant Six with a heavy-duty 3- or

4-speed manual transmission. The Six, and optional 200 hp V8, both with

standard closed crankcase ventilating system, are the most modern truck

engines you can buy. The standard transmission with wider teeth for

longer life, is the equal of heavy duty transmissions you'd pay a premium

for on comparable trucks. The clutch, with hydraulic actuation, is very

easy to operate.

STANDARD ENGINE AND TRANSMISSION

in Dodge low-tonnage models are a 140 hp Slant Six with a heavy-duty 3- or

4-speed manual transmission. The Six, and optional 200 hp V8, both with

standard closed crankcase ventilating system, are the most modern truck

engines you can buy. The standard transmission with wider teeth for

longer life, is the equal of heavy duty transmissions you'd pay a premium

for on comparable trucks. The clutch, with hydraulic actuation, is very

easy to operate.

FINAL ASSEMBLY begins with the bare frame. Models

D100 and D200 have a drop frame to lower the cab and body. Model D300 has

a frame with straight side rails. With either kind of frame, it begins

its trip down the line in a cross wise and upside down position. As it

travels along the line, the frame is fitted with Job-Rated components to

do the best job for the new owner. Springs, shock absorbers, axles, other

parts go on. Then the frame is turned over to finish its trip along the

assembly line.

FINAL ASSEMBLY begins with the bare frame. Models

D100 and D200 have a drop frame to lower the cab and body. Model D300 has

a frame with straight side rails. With either kind of frame, it begins

its trip down the line in a cross wise and upside down position. As it

travels along the line, the frame is fitted with Job-Rated components to

do the best job for the new owner. Springs, shock absorbers, axles, other

parts go on. Then the frame is turned over to finish its trip along the

assembly line.

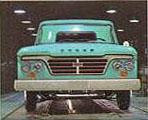

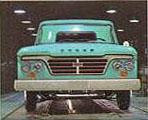

END OF THE ASSEMBLY LINE. From the minute the first

two parts of a Dodge truck were put together, back when the cab assembly

began, the inspection began. It has been going on continuously ever

since. Welds, door fit, paint, trim, everything has been carefully

checked. Now the Dodge is ready to roll off the line and head for the

toughest test of all, the exhaustive, probing final inspection. After

passing inspection, it goes into a shipping lot and then on to its new

owner to give years of dependable service.

END OF THE ASSEMBLY LINE. From the minute the first

two parts of a Dodge truck were put together, back when the cab assembly

began, the inspection began. It has been going on continuously ever

since. Welds, door fit, paint, trim, everything has been carefully

checked. Now the Dodge is ready to roll off the line and head for the

toughest test of all, the exhaustive, probing final inspection. After

passing inspection, it goes into a shipping lot and then on to its new

owner to give years of dependable service.

DODGE TRUCKS

ARE PRICED lower than most of the competition, right in line with the

rest. Your Dodge dealer can prove that to you quickly and easily. Since

January, 1962, when our new policy of running improvements was put into

effect, a great many significant engineering changes have been

incorporated in Dodge trucks to make them tougher, more economical,

tight-fisted than ever. Now, more so than at any other time in Dodge's

years of building trucks, its true that ... DODGE BUILDS TOUGH TRUCKS.

DODGE TRUCKS

ARE PRICED lower than most of the competition, right in line with the

rest. Your Dodge dealer can prove that to you quickly and easily. Since

January, 1962, when our new policy of running improvements was put into

effect, a great many significant engineering changes have been

incorporated in Dodge trucks to make them tougher, more economical,

tight-fisted than ever. Now, more so than at any other time in Dodge's

years of building trucks, its true that ... DODGE BUILDS TOUGH TRUCKS.

Notes...

This is a very descriptive advertisement, one that details many of the

manufacturing processes and standards upheld by Dodge at this time. It is

interesting to note what actually became of the extensive rust-proofing and

extra inspecting that Dodge did to make these trucks so great.

- "you can be sure of years of freedom from rust and corrosion." - this

statement, along with, "Rocker panel sills are are double coated;" makes one

wonder how long they truly intended for these trucks to last without

rusting. The rockers, which were singled out as being heavily rustproofed

were in most cases the first portions of the truck body that rusted out.

Many cabs are so severe now days that they are beyond repair. Other areas

are quite prone to rust-out on these vehicles and although manufacturing

attempted to rustproof nearly everything it still wasn't enough.

- "Since January, 1962, when our new policy of running improvements was

put into effect..." - this is a important fact to notice because after this

point, Dodge did not enact major changes at model year changeover. Rather,

all improvements were made on a "as it's engineered" basis so that all

trucks were the best available at the time. For this reason, the Spotter's

Guide must be flexible and sequence numbers of VIN's become increasingly

important, expecially before 1969.

- What about the, "Dodge Truck Building Order?" Fortunately, some people have found

theirs and have verified for me that they do exist. In fact, Bill Lammers of Ocala,

Florida was kind enough to scan his and send a copy of the scan to me. Bill tells me

that he found it under the seat, between the springs and the cushion.

| Original Dodge Truck Build Order `70 W-200 |

|---|

|

|---|

| buildorder.jpg (File Size:

94KB) |

|---|

Image courtesy of Bill Lammers, Ocala, FL

- Body inspection and flaws were easily visible on both of my truck cabs

(see the Body/Rust

page) in the form of runs in the paint, swirl marks, and marker-based

markings on the inside of the hood. Paint runs were common around the

firewall and on some other portions of the cab. Swirl marks were also made

on the larger parts (cab, bed, etc) while the paint was still wet by

"swirling" a sharp object through the fresh color coat leaving a

squiggly line where the primer shows through. This was one form of

inspecting these trucks, as was the method of marking numbers on the hood.

Also, small body tags are present on the bed, cab and possibly other parts

with a stamped in number.

- What the heck is that following the Sweptline cab into the rustproofing

booth? Rick L. wrote in to say the following: "In the photo of the cab

entering the rustproofing process it looks like a M-37 bed following behind

it. The lower tool box door and the stake pocket over the wheel well are a

dead giveaway." Thanks, Rick. This shows that perhaps all major parts of

Dodge Trucks went through the same booth(s) for rustproofing. I would have

never noticed that M-37 bed!

| Pre-History | A-100's | '61-Mid '65

Trucks | '65-67 Trucks | '68-'71 Trucks |

| CSS\Adventurer Trucks | Sweptline

Power Wagons | Medium/Heavy Duty Trucks

|

| Main Page | Online Response |

Part Sources |

Sweptline.org Forums |